Are rubber tracks suitable for all terrains? Let’s dive into this with a touch of humor and a lot of expertise from Fulian Machinery. Spoiler alert: rubber tracks are versatile, but even they have their limits!

Rubber tracks are like the Swiss Army knife of mini excavator mobility. They offer excellent performance on a wide range of terrains, making them the go-to choice for many operators. Whether you’re working on soft soil, gravel, asphalt, or even a manicured lawn, rubber tracks ensure smooth and efficient movement while minimizing damage to the surface.

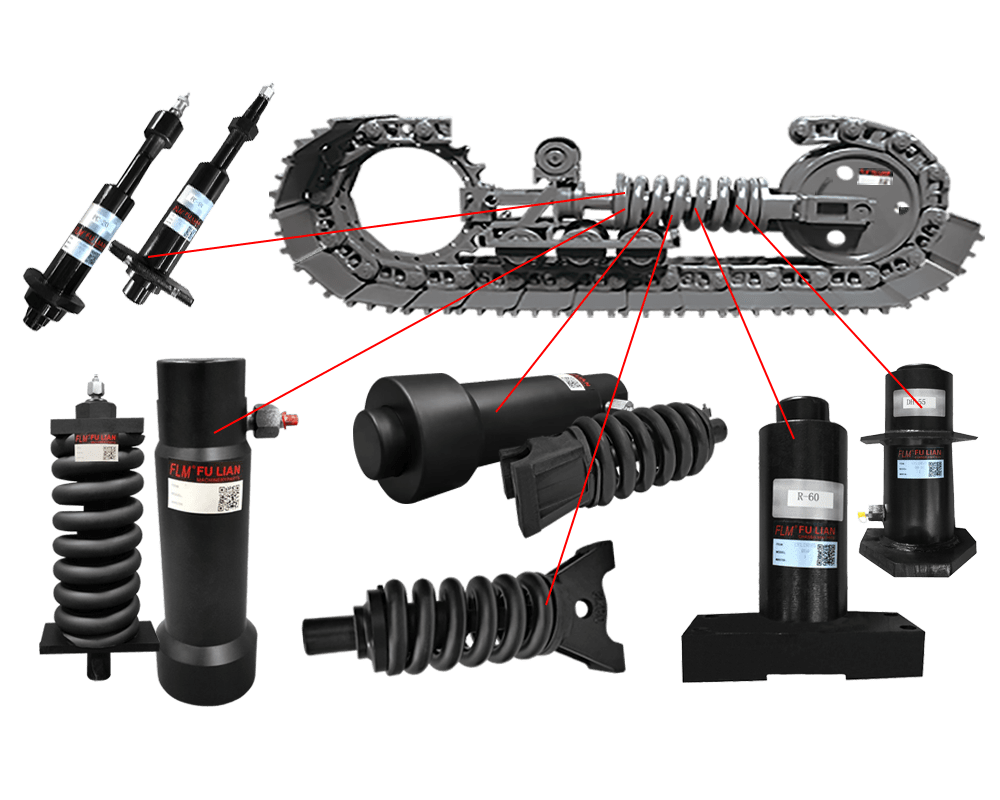

Their flexibility is thanks to their unique construction. Rubber tracks are made from high-quality rubber compounds, reinforced with steel cords and fiber layers for added strength and durability. This design allows them to absorb shocks, reducing vibrations and providing a more comfortable ride for the operator—even on rough surfaces.

But are they truly suitable for all terrains? Not quite. Imagine sending a ballerina to a demolition derby—it’s not going to end well. Similarly, rubber tracks shine in urban and light-duty settings but may falter on sharp rocks, jagged debris, or heavy mud. These conditions can cause accelerated wear or damage, like cuts, tears, or even de-tracking. For rugged terrains or projects involving heavy loads, steel tracks often outperform rubber.

One of rubber tracks’ greatest strengths is their ability to reduce ground pressure. This feature is particularly handy when working on delicate surfaces such as grass or paving stones, where steel tracks might cause unsightly damage. However, for steep slopes or rocky hillsides, rubber tracks may struggle to provide the same grip as their steel counterparts.

If your work involves frequently switching terrains, don’t worry—Fulian Machinery has your back! We offer a wide selection of high-quality rubber tracks designed for durability and versatility. Manufactured to OEM standards, our tracks are built to handle demanding environments while maintaining excellent performance and longevity. Plus, we can guide you in choosing the perfect track for your specific needs.

Proper maintenance is key to getting the most out of your rubber tracks. Regularly inspect them for signs of wear, such as cracks or embedded debris, and clean them after working in muddy or gritty conditions. Well-maintained tracks will keep your mini excavator operating efficiently and extend its lifespan.

So, are rubber tracks suitable for all terrains? Not entirely—but they’re a fantastic choice for most applications. With the right track selection and proper care, you can tackle various projects confidently. Fulian Machinery is here to help you find the best fit for your machine and provide you with reliable, high-performance undercarriage solutions.

Feel free to reach out if you need more details or have any questions. Let’s keep your mini excavator rolling smoothly, no matter the terrain!

Fulian Operation Team

2025.2.8