So, you’ve got an excavator with steel tracks, and now you’re thinking, “Wouldn’t it be nice to swap those out for rubber tracks?” Maybe you’ve heard they’re gentler on the ground, quieter, and easier on the wallet when it comes to maintenance. The idea sounds great, right? But, can you actually put rubber tracks on a steel track excavator? Well, let’s take a closer look at that idea, shall we?

First, it’s important to understand what you’re dealing with. Steel tracks and rubber tracks are like apples and oranges—they’re both types of tracks, but they have different features designed for specific tasks. Steel tracks are tough, built to withstand heavy-duty, rough terrain, and are generally used on machines that will face a lot of aggressive environments like rocky landscapes and construction sites. On the other hand, rubber tracks are softer, quieter, and better for working on delicate surfaces like paved roads or lawns, as they’re less likely to cause damage.

Now, can you simply swap one for the other? Unfortunately, the short answer is: not really. You can’t just slap a set of rubber tracks onto a steel-track machine without some serious modifications. Here’s why: Steel tracks and rubber tracks require different undercarriage systems to function properly. Steel tracks typically have a more robust frame that supports the weight and gives the track the strength it needs to handle heavy-duty applications. Rubber tracks, however, need a frame that’s specifically designed to support the rubber material and allow for the flexibility it offers.

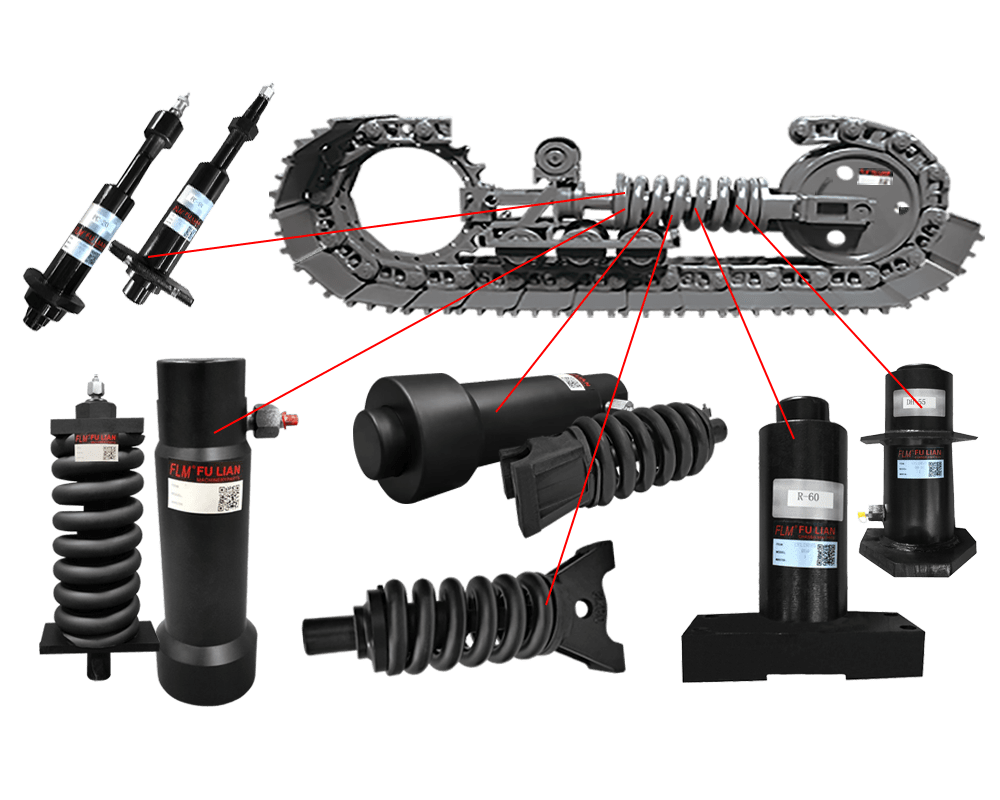

To put it in terms everyone can understand—imagine you have a pair of sturdy hiking boots (steel tracks) and a comfy pair of sneakers (rubber tracks). You wouldn’t just take the sneakers and stuff them into the boot frames, right? You’d need the right fit, the right support. Similarly, the undercarriage of your excavator needs to match the type of track you want to use. That means a frame specifically designed for rubber tracks, with compatible components like a rubber-friendly sprocket, idlers, and rollers.

Now, if you’re absolutely set on swapping out your steel tracks for rubber ones, it’s not entirely impossible. It just requires some work. In most cases, you’ll need to replace or modify the undercarriage components to accommodate rubber tracks. It’s not a simple DIY job, so it’s best to consult with a professional or your equipment dealer before you start the process. They’ll help you assess whether it’s feasible for your machine, and if it is, they’ll make sure all the parts are compatible.

At Fulian Machinery, we specialize in providing durable and reliable undercarriage parts for all kinds of excavators. Whether you’re looking for steel tracks, rubber tracks, rollers, sprockets, or anything in between, we’ve got you covered. We understand the importance of having the right equipment for the job, and our team is ready to help guide you through the process of upgrading or maintaining your machinery.

So, while it might be possible to switch from steel to rubber tracks with some modifications, it’s always a good idea to reach out to a professional before diving in. If you’re in the market for quality undercarriage parts, or you need expert advice, feel free to reach out to us! We’re here to make sure your excavator is up to the task, no matter what tracks you decide to go with.

Fulian Operation Team

2024.12.28