Can worn sprockets damage the tracks of a mini excavator? The answer is a resounding “Yes!” Worn sprockets and tracks have a relationship that can quickly turn sour if one gets neglected. Let’s explore this with a touch of humor and a serious dose of expertise from Fulian Machinery.

Picture your mini excavator’s sprockets and tracks as a dynamic duo. When they’re in sync, they tackle tough jobs effortlessly. But when the sprockets are worn, it’s like trying to dance in shoes that don’t fit—they’re out of rhythm, and somebody’s bound to trip. Worn sprockets can accelerate the wear and tear on your tracks, leading to costly repairs and downtime.

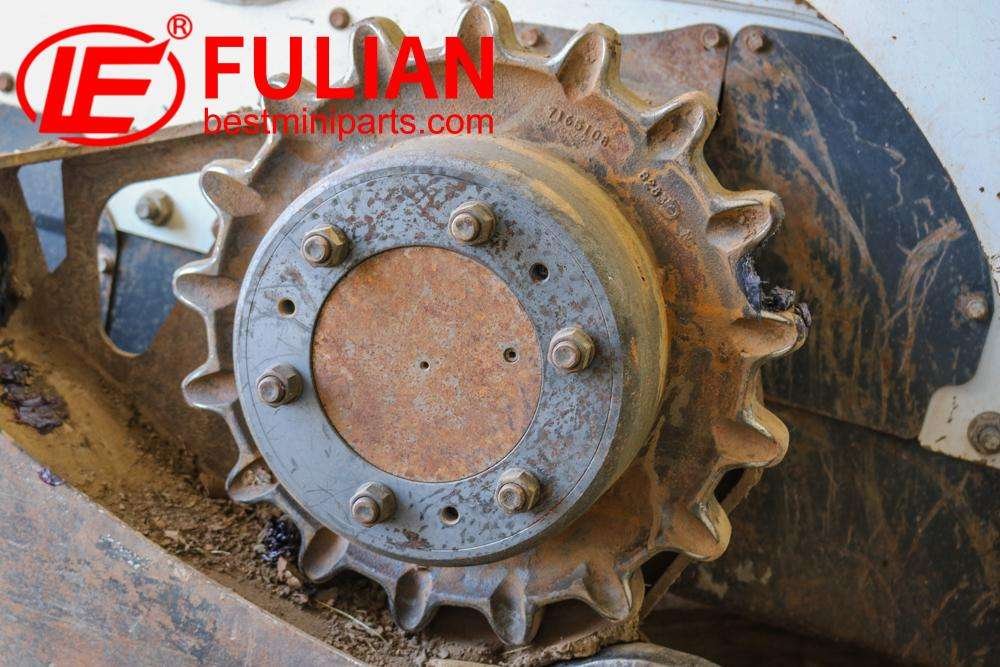

Here’s how it happens. Sprockets are designed to engage with the track links smoothly, ensuring even power distribution. When sprocket teeth wear down, they lose their precise shape, causing the track links to misalign or slip. This misalignment creates uneven stress on the tracks, leading to premature stretching, cracking, or even breaking. In essence, worn sprockets don’t just work poorly—they actively sabotage your tracks.

You might notice some telltale signs that your sprockets are turning against your tracks:

- A jerky ride, as if your mini excavator suddenly developed stage fright.

- Increased noise, which might sound like your machine is begging for a spa day.

- Visible wear patterns on the sprocket teeth or uneven track wear.

Ignoring these signs is like ignoring a leaky faucet—it starts small but can quickly escalate into a major problem. Regular inspections are essential to catch sprocket wear early. Fulian Machinery recommends checking for signs of rounding or chipping on the sprocket teeth and ensuring the track links fit snugly without excessive play.

When it’s time to replace your sprockets, don’t skimp on quality. Fulian Machinery offers top-tier sprockets crafted to OEM standards. Made from high-grade materials and treated for maximum durability, our sprockets are engineered to extend the lifespan of your tracks and keep your mini excavator performing at its peak.

The good news is that replacing worn sprockets is a relatively simple and cost-effective solution compared to the expense of replacing damaged tracks. Pairing new sprockets with your existing tracks or replacing both at the same time ensures optimal compatibility and performance.

At Fulian, we take pride in providing durable, high-performance undercarriage parts that save you time, money, and frustration. Our sprockets are designed to endure the toughest conditions and keep your equipment running smoothly. With over two decades of expertise, we’re here to guide you through every step of maintaining your mini excavator.

So, can worn sprockets damage your tracks? Absolutely. But with Fulian Machinery by your side, you can prevent the problem before it starts. Feel free to reach out if you need more details or have any questions—we’re here to keep your equipment running like new!

Fulian Operation Team

2025.2.7