Changing an excavator sprocket might not directly affect the engine, but trust me, it can definitely have an impact on your overall performance. Think of the sprockets as the gears in a well-oiled machine—if one part starts to slip, it can create a ripple effect throughout the system, even if the engine is chugging along just fine.

When you replace your sprockets, it’s like upgrading your shoes before a marathon—you’re preparing for peak performance. A worn sprocket can cause the tracks to slip or wear unevenly, which may result in increased drag on the undercarriage system. This extra resistance, even if subtle, puts more strain on the whole machine, including the engine. You can think of the engine working harder to maintain the same level of power when the sprockets are failing as similar to driving a car with old tires—more fuel is burned, and more power is needed to keep the wheels (or tracks) turning smoothly. So, while the engine itself might not be directly impacted by the sprocket replacement, the efficiency and overall health of the machine could take a hit if you ignore the problem.

Another thing to consider is track tension. If the sprockets are worn or misaligned, they can affect how the tracks sit, which in turn affects track tension. Improper tension leads to increased strain on both the undercarriage and the engine. A loose track may skip teeth or wear out faster, while a tight track might overexert the engine and other components—either way, it’s not a win for the machine. The result? More fuel consumption and a higher risk of engine stress over time.

Sprockets play a vital role in distributing power from the engine to the tracks. If the sprockets are not working optimally, the engine may need to work harder to compensate. Over time, this can lead to unnecessary wear on the engine itself. This is why regular maintenance and timely sprocket replacements are crucial—just like checking your car’s tires before that long road trip. Keep your sprockets in top shape, and the rest of your machine will thank you by working more efficiently.

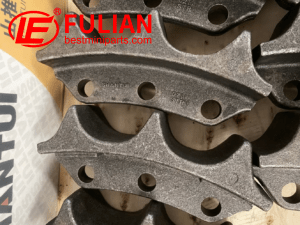

At Fulian Machinery, we understand the importance of reliable undercarriage parts that keep everything running smoothly. That’s why our sprockets are made with high-quality materials, built to withstand the rigors of tough construction sites. Our sprockets ensure smooth, consistent engagement, preventing unnecessary strain on your excavator’s engine and other critical components. When you choose Fulian, you’re not just replacing a part; you’re investing in long-lasting efficiency, durability, and reduced engine strain.

So, does changing the sprockets affect the engine? Well, it’s not a direct hit, but it certainly plays a role in the bigger picture. Don’t let worn-out sprockets slow down your excavator—contact Fulian Machinery today for top-tier sprockets that will keep your engine and your operations running at their best!

Fulian Operation Team

2024.12.20