When an excavator’s track keeps coming off, it can really slow things down. Here’s a plain-English look at why this might happen:

-

Tension Trouble: The track has to be tight enough but not too tight. If it’s too tight, it could break. If it’s too loose, it could slip off. Think of it like a belt for your pants; if it’s not adjusted right, it doesn’t work well.

-

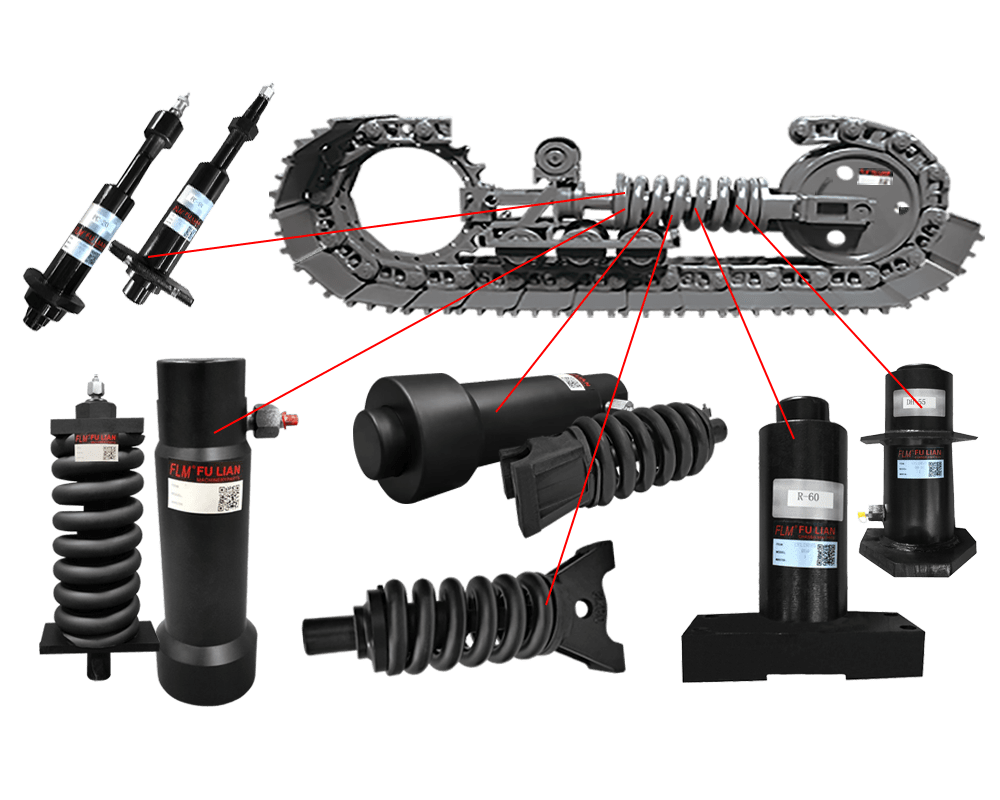

Wear and Tear: The track rolls over several parts, like sprockets and rollers. Over time, these can wear down. When they do, the track might not fit as well and could come off. It’s a bit like how a worn-out shoe doesn’t fit your foot properly anymore.

-

Debris: Things like rocks or dirt can get caught in the track system. This can push the track out of place. Imagine walking with a pebble in your shoe; it’s uncomfortable and you want to remove it, right?

-

Installation Issues: If the track wasn’t put on correctly in the first place, it’s more likely to come off. It’s similar to putting a bike chain on wrong; it’s just not going to stay on the gears.

-

Driving Habits: The way the excavator is driven can affect the track. Sharp turns and fast movements can make it more likely for the track to slip off. It’s like taking a corner too fast in a car; you might lose control.

-

Alignment: The track needs to be perfectly aligned with the sprockets and rollers. If it’s off, even by a little, it can slip off. Think of it like a train on tracks—everything needs to be lined up for it to stay on track.

-

Undercarriage Issues: Damage to the undercarriage from use or impacts can cause the track to come off. It’s similar to driving a car with damaged suspension; it affects everything else.

-

Extreme Conditions: Operating in very hot or cold temperatures, or on rough terrain, can cause problems. The track material can expand or contract with the temperature, or get damaged from rough ground. It’s like how a door might stick in summer but not in winter due to the wood expanding and contracting.

To keep the excavator running smoothly, here are some tips:

- Maintain Proper Tension: Regularly check and adjust the track tension.

- Inspect and Replace Worn Parts: Keep an eye on the sprockets, rollers, and the track itself for wear.

- Keep It Clean: Regularly remove any debris from the track area.

- Ensure Correct Installation: Always follow the manufacturer’s guidelines for track installation.

- Drive Carefully: Avoid harsh maneuvers to reduce strain on the tracks.

- Check Alignment: Regularly ensure everything is lined up correctly.

- Inspect the Undercarriage: Look out for any damage or wear that might affect the track.

- Account for Weather: Be mindful of operating conditions and adjust your maintenance accordingly.

Regular upkeep is key to preventing track disengagement and keeping your excavator on the move.

Fulian Operation Team

2024.5.20