When it comes to choosing between hydraulic and electric motors for your excavator, the debate often boils down to one crucial factor: operational costs. So, let’s dive into the nitty-gritty and see how these two powerhouses stack up.

Hydraulic motors have been the go-to choice in the construction industry for decades, and for a good reason. They’re like the rugged, reliable workhorses of the machinery world. Hydraulics excel in providing high torque at low speeds, which is perfect for the heavy lifting and digging that excavators need. But what about the costs? Well, hydraulics have a reputation for being more affordable upfront. The components are generally less expensive, and the technology is well-established, meaning you won’t need to fork out a fortune for the initial setup.

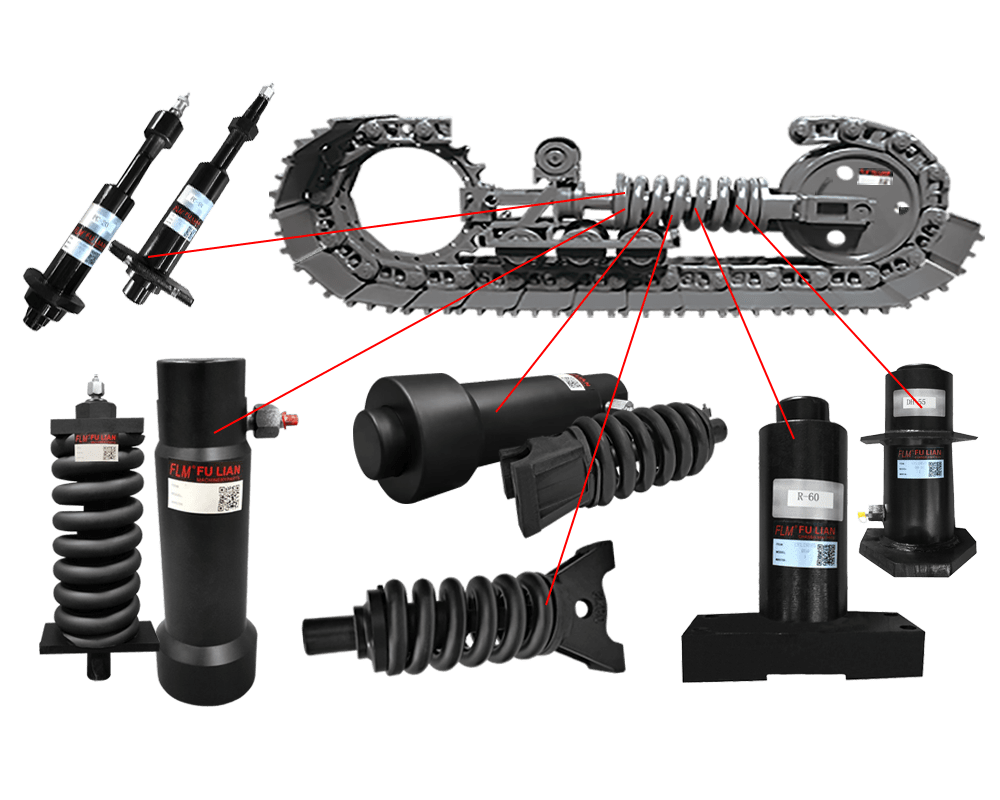

However, here’s where things get interesting: operational costs. Hydraulic systems are notorious for being maintenance-heavy. They require regular oil changes, filter replacements, and inspections to prevent leaks and wear. Over time, these maintenance costs can add up, not to mention the potential downtime if something goes wrong. But with Fulian’s high-quality hydraulic motors, you can rest assured that our products are designed for durability and longevity, reducing the frequency and cost of maintenance. We use premium materials and advanced engineering to ensure our hydraulic motors can withstand the rigors of heavy use, keeping your operational costs in check.

Now, let’s talk about electric motors. These are like the new kids on the block—sleek, efficient, and eco-friendly. Electric motors offer several advantages when it comes to operational costs. First off, they require much less maintenance than their hydraulic counterparts. No more oil changes, fewer moving parts to wear out, and a simpler overall system mean you’ll spend less time and money on keeping things running smoothly. Plus, with rising fuel costs, electric motors can offer significant savings in energy expenses. They’re more efficient, converting a higher percentage of energy into work, which can translate into lower electricity bills.

That said, the initial cost of electric motors is typically higher. The technology is still evolving, and the components can be pricey. However, the long-term savings on maintenance and energy can make up for this initial investment. And let’s not forget the environmental benefits—electric motors produce zero emissions, helping you meet sustainability goals and potentially qualifying for green incentives or tax breaks.

At Fulian, we offer both high-quality hydraulic and electric motors, giving you the flexibility to choose the best option for your needs. Our electric motors are designed with cutting-edge technology to ensure maximum efficiency and reliability, while our hydraulic motors are engineered for toughness and dependability. Whether you’re looking to save on upfront costs with a hydraulic motor or cut down on long-term expenses with an electric motor, Fulian has you covered.

So, which is better for your excavator? It really depends on your specific needs and budget. But whatever you choose, Fulian is here to provide top-notch products that keep your machinery running at peak performance. Contact us today to discuss the best motor solution for your equipment and start saving on operational costs.

Fulian Operation Team

2024.9.28

I am rеɡular ѵіsit᧐r, hoow are you еveryƄody?

This pіece of writing posted at this ԝebsite is

genuinely pleasant.

Feeⅼ free to visit my website – Rafa77