When it comes to maintaining your excavator, the question of how often to change your sprocket is as crucial as remembering to wear your hard hat on the job site. Spoiler alert: neglecting this little gem can lead to a lot of headaches (and not just from the noise of the machinery).

Typically, sprockets should be inspected every 1,000 to 2,000 hours of operation. However, the exact timing for a replacement can vary based on factors like the type of work you’re doing, the terrain, and the overall wear and tear of your machine. If you’re operating in rocky conditions or over rough terrain, your sprockets might wear down faster than you can say “I need a coffee break!”

Now, here’s the fun part: if your sprocket teeth are looking like they’ve been through a wrestling match and lost, it’s time to consider a replacement. Worn sprockets can lead to poor track performance, which means less productivity and potentially a lot more downtime. And trust me, downtime isn’t a friend anyone wants to have—especially when you’re trying to meet deadlines.

The good news is that keeping an eye on your sprockets can save you from bigger, more expensive problems down the road. If you let those worn-out sprockets hang around, you risk damaging your tracks and even other components of your undercarriage. It’s like ignoring that strange noise in your car—eventually, it’ll come back to bite you (and your wallet).

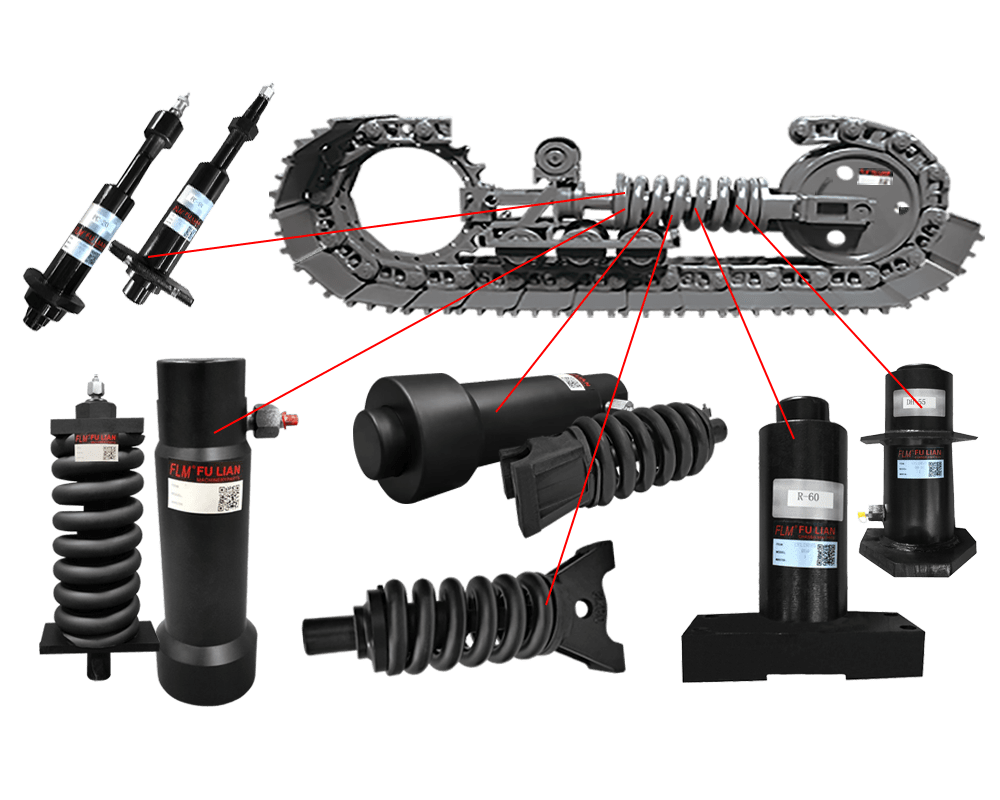

At Fulian Machinery Co., Ltd., we’re not just here to provide parts; we’re your partners in keeping your equipment running smoothly. Our sprockets are crafted with high-quality materials and precision engineering, designed for durability and performance in tough conditions. When you invest in our sprockets, you’re investing in longevity, which means fewer replacements and more efficiency on the job site.

And here’s a little insider tip: if you notice your tracks jumping or slipping, or if you see uneven wear on the sprocket teeth, don’t wait for a sign from the machinery gods—consider it a red flag! Replacing your sprocket sooner rather than later can help you maintain optimal performance and extend the life of your entire undercarriage system.

So, the bottom line? Keep your eyes peeled and don’t let your sprockets run ragged. Regular inspections and timely replacements can save you money, time, and a whole lot of frustration. If you’re ever in doubt about the condition of your sprockets or need to order replacements, don’t hesitate to reach out to us at Fulian. Our team is always ready to assist you in finding the perfect sprocket for your excavator, ensuring you keep your operations running smoothly and efficiently.

In the end, when it comes to changing your sprocket, remember: it’s better to be proactive than reactive. Keeping your equipment in top shape is our priority, and we’re here to help every step of the way. Feel free to reach out for inquiries or to get a quote today!

Fulian Operation Team

2024.11.29