When replacing a sprocket on an excavator, whether you need a new chain (commonly referred to as the track chain or track) can depend on a variety of factors, including the condition of the existing chain, the degree of wear on the old sprocket, and the expected longevity of the undercarriage components.

Assessing Chain and Sprocket Wear

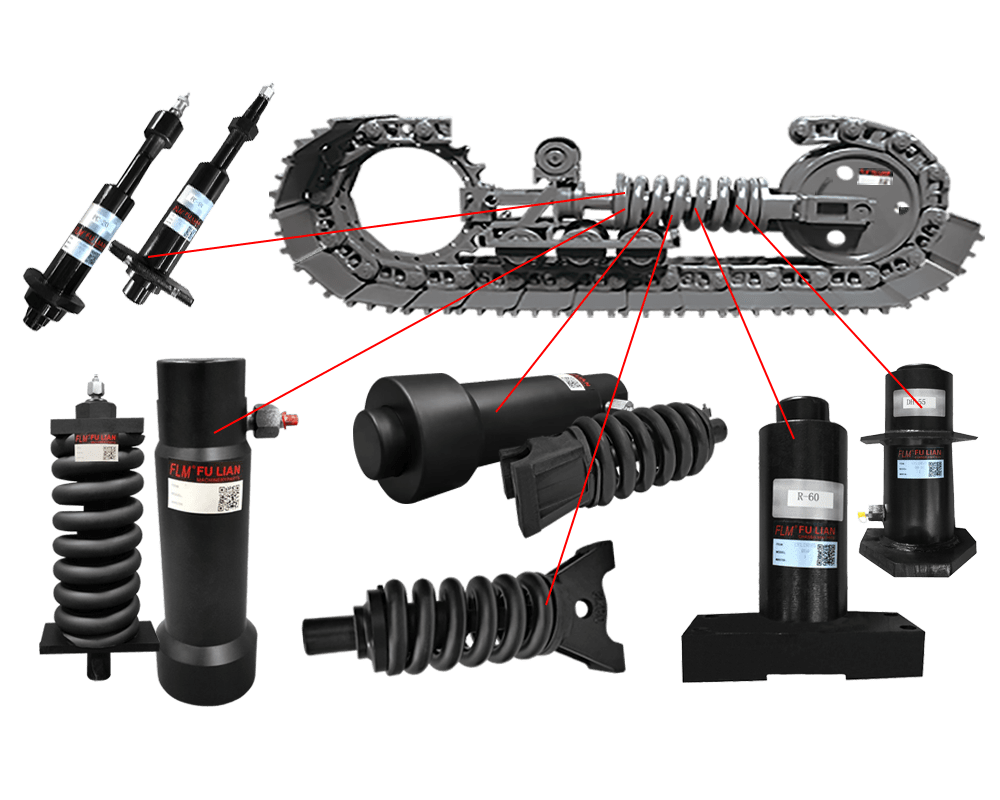

An excavator’s sprocket and chain work in unison to propel the machine. Over time, these parts wear down due to the constant friction and load. The sprocket teeth wear into a sharp or hooked profile, and the chain components – pins, bushings, and links – also wear out.

An excavator’s sprocket and chain work in unison to propel the machine. Over time, these parts wear down due to the constant friction and load. The sprocket teeth wear into a sharp or hooked profile, and the chain components – pins, bushings, and links – also wear out.

-

Even Wear: Ideally, undercarriage components should wear evenly and be replaced at the same time to maximize the operational lifespan of the undercarriage. If the sprocket is worn out, it’s likely that the chain is also nearing the end of its service life.

-

Mismatched Wear: Installing a new sprocket on a worn chain, or vice versa, can accelerate the wear of the new component. A new sprocket may not mesh well with a chain that has stretched or worn, leading to increased stress and quicker failure.

Professional Inspection

It is recommended to get a professional inspection of the undercarriage. A technician can measure the wear on the chain’s pins and bushings, as well as the wear on the links, to determine if it’s matching with the wear on the sprockets.

It is recommended to get a professional inspection of the undercarriage. A technician can measure the wear on the chain’s pins and bushings, as well as the wear on the links, to determine if it’s matching with the wear on the sprockets.

Economic Consideration

While it may seem more economical to replace only one component, consider the following:

While it may seem more economical to replace only one component, consider the following:

-

Shortened Lifespan: A new sprocket paired with an old chain could potentially shorten the lifespan of both.

-

Work Downtime: A mismatched undercarriage may lead to a breakdown, causing more significant downtime and higher costs for emergency repairs.

-

Long-term Cost: The total cost of ownership may be less when replacing both the sprocket and chain at the same time, as you may avoid additional labor costs and the potential for unscheduled maintenance.

Preventative Maintenance

To avoid premature wear, regular maintenance is essential:

To avoid premature wear, regular maintenance is essential:

-

Track Tension: Keeping the track tension within the manufacturer’s recommended specifications ensures that the sprocket and chain are not unduly stressed.

-

Alignment Checks: Ensuring that the excavator’s tracks are correctly aligned will help to evenly distribute wear across the undercarriage components.

-

Daily Cleanouts: Removing debris from the track and sprocket area will reduce wear.

Conclusion

A worn sprocket usually implies similar wear on the chain, so it is generally advisable to replace both components simultaneously. Alongside professional advice, consider the economic implications of partial undercarriage replacements and the potential for further damage and operational inefficiency. Therefore, while it isn’t an outright requirement to replace the chain when you install a new sprocket, it is often the best practice for maximizing machine performance and reducing long-term costs. Maintaining a complete and holistic approach to undercarriage maintenance will help ensure the durability and reliability of your excavator’s undergear, supporting continued performance and productivity.

A worn sprocket usually implies similar wear on the chain, so it is generally advisable to replace both components simultaneously. Alongside professional advice, consider the economic implications of partial undercarriage replacements and the potential for further damage and operational inefficiency. Therefore, while it isn’t an outright requirement to replace the chain when you install a new sprocket, it is often the best practice for maximizing machine performance and reducing long-term costs. Maintaining a complete and holistic approach to undercarriage maintenance will help ensure the durability and reliability of your excavator’s undergear, supporting continued performance and productivity.

Fulian Operation Team

2024.2.10