Yes, replacing the steel tracks of an excavator with rubber tracks is possible, but it’s akin to putting a new pair of shoes on your excavator. Just like finding the right shoes involves more than just size; swapping tracks is about ensuring compatibility, purpose, and fit.

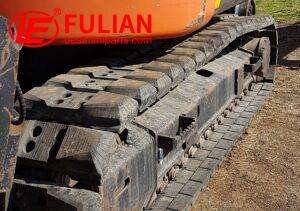

Steel tracks, the equivalent of rugged outdoor boots for your excavator, excel in harsh, abrasive environments. They’re built tough to navigate through rubble, rocks, and hard surfaces without flinching. However, these steel giants can be harsh on softer terrains, where a gentler touch is required.

Enter rubber tracks, the sneakers for your excavator, designed for less invasive footprints on sensitive grounds like landscaped gardens or paved pathways. They reduce damage and are quieter, making them preferred for urban or residential areas.

However, switching from steel to rubber isn’t as straightforward as snapping your fingers. Here’s why:

-

Compatibility Check: Not all excavators are designed to switch tracks easily. You’ll need to check with your manufacturer or a specialist to see if your model accommodates rubber tracks without causing harm or reducing efficiency.

-

Undercarriage Adaptation: Some excavators may need modifications to their undercarriage to fit rubber tracks properly. This can range from simple adjustments to more complex alterations, potentially adding to the overall cost.

-

Performance Shifts: Swapping to rubber can change how your excavator handles. While you’ll likely see a decrease in damage to paved or delicate surfaces, there might be a compromise in durability and grip when dealing with harsher terrain.

-

Cost Analysis: Initially, rubber tracks might seem more economically friendly due to their lower cost. However, considering their wear rate, especially in tough conditions where they might not last as long as their steel counterparts, you could end up spending more in the long run.

In essence, while converting your excavator from steel to rubber tracks is possible, it involves a thorough evaluation of compatibility, potential adjustments, a balancing act between performance needs and operational costs, and perhaps most importantly, consulting with professionals who can guide you through the process. Just like with shoes, what matters most is the right fit for your specific needs.

Fulian Operation Team

2024.7.17