Running a powerful excavator every day means stress, dust, vibration, and extreme working conditions. One of the most important but often overlooked components is the idler group. A damaged or neglected idler assembly can lead to serious alignment problems, increased wear on other undercarriage parts, and expensive downtime.

Operators may not notice idler wear immediately. The symptoms appear slowly—track tension becomes inconsistent, the track drifts during operation, or unusual noise develops near the front end of the machine. Ignoring these signs leads to costly chain replacements or, worse, complete failure of the track system.

Regular idler maintenance solves most of these issues early. Start by checking for oil leaks around the seal. Leaking oil indicates worn-out bushings or cracked seals. Inspect the idler surface for cracks or deep grooves. These weaken the structure and reduce the contact area, causing uneven load distribution across the track links.

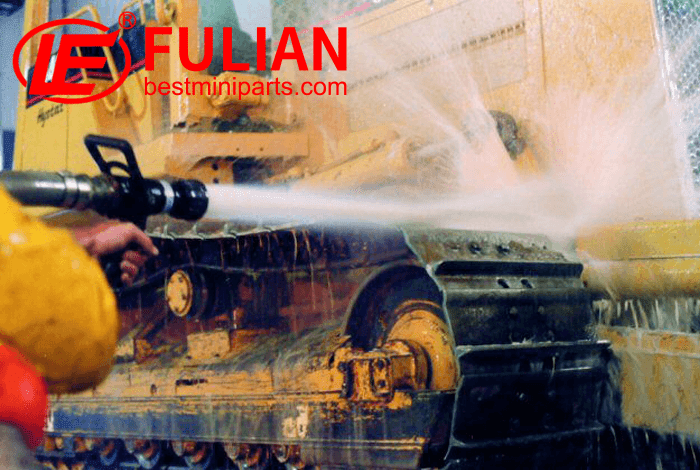

Clean the idler often. Built-up mud and debris increase stress on the tension system. This also hides early signs of damage. A simple wash-down at the end of each shift helps extend lifespan. Also, check the spring recoil mechanism. Weak tension causes track slippage, which shortens the life of both the idler and the track chain.

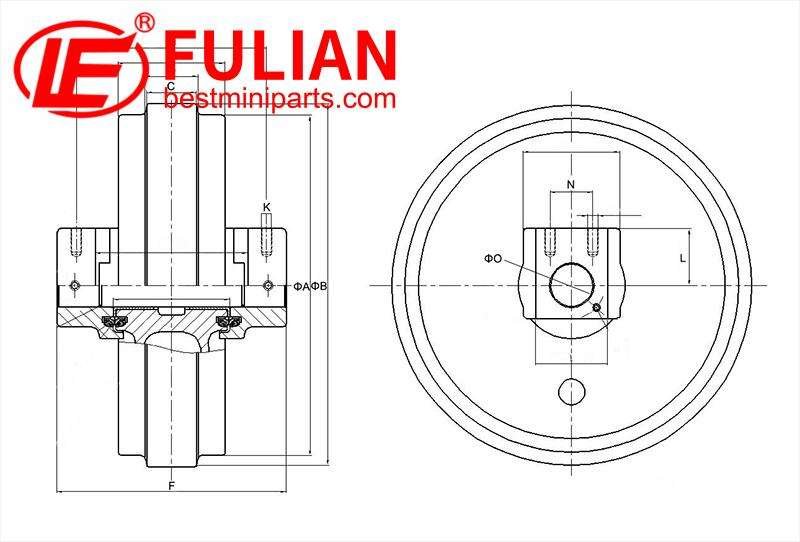

Measuring the wear limit is key. If the flange or tread width drops below OEM minimum specs, replacement is necessary. Using worn parts increases vibration and weakens the final drive system.

At Fulian Machinery, we offer precision-made idler groups for a wide range of excavators, from 1-ton mini units to 50-ton mining machines. Our idlers are built using heat-treated forged steel, high-grade shaft seals, and CNC-machined for consistent quality. We use robust recoil springs that last under continuous use, even in quarry, oilfield, or construction environments.

Fulian also provides technical support and stock availability for fast dispatch. Whether you need individual idlers or a full undercarriage kit, we help reduce downtime and lower your maintenance cost. Our team supports clients in over 60 countries, with quality that matches or exceeds OEM standards.

Take control of your machine’s reliability. Contact Fulian Machinery for a quote or expert guidance on maintaining or replacing your excavator idler group. Strong support starts with the right part.

Fulian Operation Team

2025.3.22