Every excavator operator knows that tracks are the backbone of machine movement. They handle constant friction, heavy loads, and rough terrains. Yet, track wear remains one of the most common and expensive maintenance issues in construction equipment. The good news is, with a few simple daily habits, you can greatly extend the lifespan of your tracks, reduce repair costs, and keep your excavator performing at its best.

The first and most essential tip is cleaning your tracks every day. Mud, rocks, and debris often get trapped between the rollers and links. When ignored, this buildup acts like sandpaper, grinding down metal surfaces and accelerating wear. After each workday, use a pressure washer or a strong hose to clear out dirt and stones from the undercarriage and tracks. A clean track not only runs smoother but also helps you spot damage early.

Next, check track tension regularly. Incorrect tension is one of the biggest causes of premature wear. Tracks that are too tight create unnecessary pressure on rollers and sprockets, while loose tracks can derail or slap against components. Always follow the manufacturer’s specifications for proper tension, and adjust according to your working conditions. For example, slightly looser tension is ideal for muddy or wet environments to avoid excess mud accumulation.

Another important habit is inspecting the undercarriage daily. Look for oil leaks around rollers, cracks in links, and missing bolts or pins. Small problems can turn into major breakdowns if left unchecked. A quick visual inspection before and after work takes just a few minutes but can save hours of downtime later.

Then, pay attention to how you operate the excavator. Avoid making sharp turns or pivoting the machine on one track, as this increases wear on the outer edges. Try to minimize traveling long distances at high speed. Smooth and planned movements reduce stress on the track system and make your components last longer.

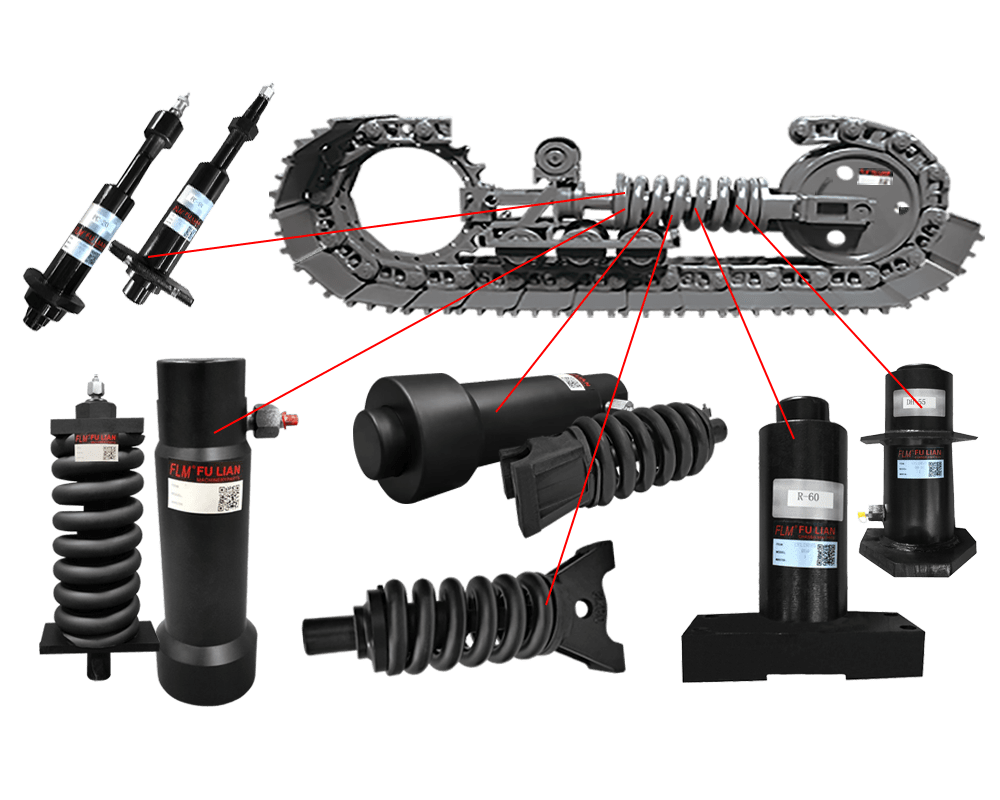

Finally, invest in quality replacement parts. Even the best maintenance can’t stop natural wear forever. When the time comes for replacements, use high-quality track chains, rollers, and sprockets designed for your specific excavator model. Reliable parts ensure smoother operation, better alignment, and longer service intervals.

Regular care combined with premium components makes all the difference. Many operators underestimate how much a clean, well-tensioned track can improve performance and fuel efficiency. The more consistent your routine, the better your machine will perform.

If you’re looking for durable, factory-standard undercarriage parts for your excavators, Fulian Machinery offers a complete range of solutions. Our parts are designed for strength, precision, and long-term stability, helping your equipment stay in top shape no matter the job site.

Keep your tracks in good health, and your excavator will reward you with smoother operation, lower fuel costs, and fewer breakdowns. Take the time to follow these simple daily steps and experience the difference in reliability and performance. For quality replacement parts or professional advice, contact Fulian Machinery today and keep your machine ready for every challenge.

Fulian Operation Team

2025.11.10