Excavator track chains work harder than a coffee-fueled construction crew, constantly grinding through mud, rocks, and whatever else the job site throws at them. But even the toughest track chains need proper maintenance—ignore them, and you’ll be shelling out for replacements faster than you can say ‘undercarriage failure.’ So, what’s the secret to keeping your excavator’s track chains in top shape?

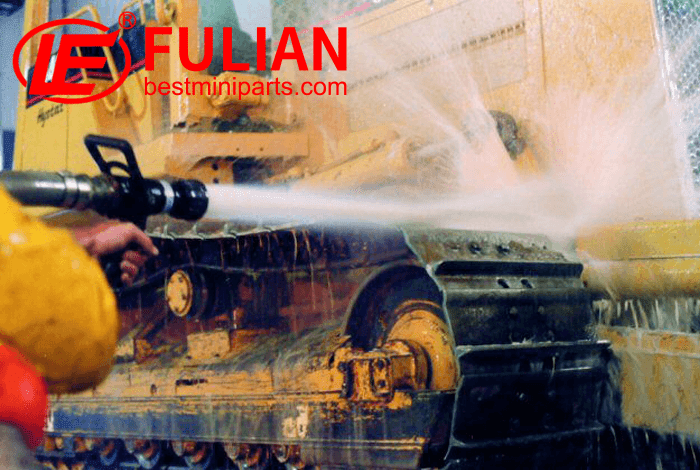

First things first—keep them clean! Your track chains aren’t fans of the extra weight from dried mud, packed dirt, or debris. Think of it like walking around with bricks in your shoes—not fun, right? A quick washdown at the end of each workday prevents unnecessary wear and corrosion. High-pressure water or a good old-fashioned shovel will do the trick, but avoid blasting seals and pins directly, unless you enjoy surprise breakdowns.

Next, adjust track tension regularly. If your track chains are too tight, they’ll stretch and wear prematurely. Too loose? They’ll slap around like a fish out of water, causing damage to rollers, sprockets, and idlers. The sweet spot depends on your machine and terrain, but a general rule is about 2 inches (50mm) of sag when lifted off the ground. Don’t guess—check your manufacturer’s specs or ask the pros at Fulian.

Lubrication is non-negotiable. Dry, squeaky track pins and bushings are a recipe for disaster—friction increases, wear accelerates, and before you know it, you’re looking at costly replacements. A high-quality lubricant designed for track chains helps reduce metal-on-metal grinding and prevent rust. And no, motor oil won’t cut it—use a proper undercarriage grease that’s built for the job.

Speaking of wear, keep an eye on pin and bushing wear. Over time, these components rotate and wear unevenly, causing the track chain to “stretch.” This isn’t real stretching—just wear that makes the chain longer and less efficient. Regular inspections and timely bushing turns can extend track life significantly. Wait too long, and you’ll be shopping for new chains instead of just flipping the bushings.

Another pro tip—rotate your tracks if you notice uneven wear. If your excavator spends more time turning in one direction, one side of the track chain will wear out faster than the other. Swapping left and right tracks (if your machine allows it) balances the wear and gives you extra life from each set. Think of it like rotating your car tires—small effort, big savings.

And of course, don’t ignore the rest of your undercarriage. Your track chains work hand-in-hand with rollers, sprockets, and idlers. A worn-out sprocket will eat up your chain like a bad habit. Regular undercarriage inspections will catch small issues before they turn into expensive problems. At Fulian, we supply track chains designed for maximum durability and minimum downtime—but even the best parts need a little TLC.

Bottom line? A little maintenance goes a long way. Keep your track chains clean, properly tensioned, well-lubricated, and regularly inspected, and they’ll reward you with a long service life and lower operating costs. Need new track chains that won’t let you down? Contact Fulian today and get your machine back in action!