When it comes to a mini excavator’s undercarriage, rollers might not always get the spotlight, but trust me, they deserve a standing ovation. These little heroes work behind the scenes to ensure that your machine stays stable, moves efficiently, and lasts longer—without them, your excavator would be like a car without tires. Not very functional, right? So, let’s dive into the vital functions of rollers and why they’re absolutely essential for your mini excavator’s performance.

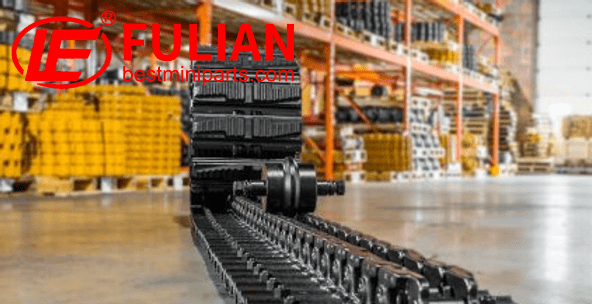

First and foremost, rollers serve as load-bearing components. They’re responsible for distributing the weight of the excavator across the tracks and ensuring that the machine remains balanced and stable. Think of them as the unsung bodyguards of your undercarriage, keeping everything steady and in place so that you don’t end up with an unstable machine that’s prone to wear and tear. At Fulian, we manufacture rollers that are built to handle tough jobs, from heavy lifting to navigating rocky, uneven terrain, ensuring smooth operation throughout.

Another important role rollers play is in the reduction of track wear. As the tracks move along the ground, they need to stay in constant contact with the rollers, ensuring even pressure distribution. This helps to prevent excessive friction between the tracks and the ground, which could otherwise cause damage over time. Fulian’s rollers are designed with high-quality materials that resist wear, ensuring your mini excavator’s tracks stay in tip-top condition for longer. After all, if the tracks are the shoes, the rollers are the soles—they’re taking all the pounding, so they need to be durable!

Track alignment is another crucial function of rollers. They help guide the tracks to move smoothly around the sprockets, ensuring that the entire system stays aligned and functions without issues. If the rollers aren’t doing their job properly, you could experience misalignment that causes the tracks to slip off, which can be a real headache during a job. With Fulian’s rollers, you won’t have to worry about that—our parts are engineered for precision and designed to keep everything running smoothly.

Let’s not forget the reduction of vibration and shock. Excavators, particularly mini ones, work in rough environments where vibrations and shocks are constant. Rollers absorb and distribute these forces, preventing unnecessary strain on other parts of the undercarriage. This helps to extend the lifespan of your mini excavator and keep it performing at its best. At Fulian, we use high-quality seals and bearings in our rollers, ensuring maximum shock absorption and stability.

So, if you want your mini excavator to perform at its best, you can’t overlook the importance of rollers. They’re not just there to keep things rolling (pun intended), but to ensure that your machine stays stable, efficient, and reliable. And if you’re looking for high-quality rollers that offer all of these benefits, Fulian has you covered. We offer rollers designed for heavy-duty performance, made with the best materials to handle the most demanding job sites. Reach out to us today, and let’s keep your mini excavator running like a champ!

Fulian Operation Team

2025.1.17