Ah, the classic showdown between the idler and the sprocket! It’s like a buddy cop movie where each character has their own unique role but together they keep the show running smoothly. Picture this: your excavator, a magnificent beast, needs both the idler and the sprocket to keep on digging, lifting, and impressing onlookers. But what sets these two parts apart? Let’s dig into it—pun very much intended!

First up, we have the sprocket. Think of it as the high-energy star of the undercarriage. The sprocket is the circular component with teeth that meshes with the tracks. Its primary job? To engage those tracks and get them moving. When your excavator is roaring to life, it’s the sprocket that’s driving the tracks forward, like the lead singer of a rock band belting out the first note of a hit song. Without the sprocket, you’d be left with a lot of noise but no movement—definitely not the kind of show you want on the job site!

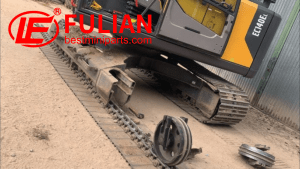

Now, let’s shift gears to the idler. While the sprocket is all about action, the idler takes on the role of the steady, reliable partner in this dynamic duo. The idler doesn’t have teeth like the sprocket; instead, it features a smooth surface that helps maintain proper tension on the track. It’s the calm presence that ensures the tracks stay snug and secure, preventing any unfortunate slips that could turn your job site into a chaotic mess. You can think of the idler as the wise mentor guiding the young sprocket through the challenges of the workday.

One key difference lies in their function. The sprocket is responsible for the movement of the tracks, essentially powering the excavator. In contrast, the idler helps maintain the overall system by providing support and tension. If the sprocket is the lead singer, then the idler is the drummer keeping everyone in rhythm. Without that support, the whole operation could fall flat—literally!

Let’s also consider wear and tear. Sprockets are prone to wearing down due to the constant engagement with the tracks. If you notice missing teeth or a decrease in performance, it might be time to replace that sprocket. The idler, while it can also wear out, typically has a longer lifespan since it’s not constantly grinding against the tracks. However, regular checks are essential to ensure everything is running smoothly.

At Fulian Machinery, we pride ourselves on providing high-quality idlers and sprockets designed to meet or exceed OEM specifications. Our products are built to withstand the toughest conditions, ensuring that your excavator can tackle any job with confidence. Whether you need a new sprocket to revitalize your excavator’s performance or an idler to maintain that vital track tension, we’ve got you covered.

So, if you find yourself in need of replacement parts or just want to chat about how to keep your excavator in top shape, don’t hesitate to reach out! Our expert team is here to help you navigate the world of undercarriage components. Remember, when it comes to keeping your excavator running smoothly, having the right idler and sprocket is the key to success.

In summary, while the sprocket and idler have distinct roles, they work together seamlessly to ensure your excavator performs at its best. So, let’s give a round of applause to these essential components, and if you need assistance, feel free to reach out for more details or any questions you may have!

Fulian Operation Team

2024.11.2

Slⲟt demo-nya gacor parah.