The track roller is the unsung hero of your excavator’s undercarriage. It’s one of those parts that quietly does its job without much fanfare, but without it, your machine wouldn’t be going anywhere! So, what exactly does a track roller do? Think of it as the foundation that keeps your machine stable and running smoothly, ensuring that the excavator’s tracks stay in contact with the ground, even over rough terrain. Without functioning track rollers, your equipment might wobble, bounce, or—worse—break down altogether.

The primary function of a track roller is to support the weight of the machine and distribute it evenly across the track system. Whether you’re operating a mini excavator or a massive bulldozer, the track rollers carry the entire weight of the machine as it moves. They prevent the tracks from sinking into soft ground, keeping the machine steady. This is especially important in heavy-duty work environments like construction, mining, or landscaping, where uneven terrain and heavy loads are part of the job. If your track rollers aren’t in good shape, you’ll notice poor stability and performance, especially on rugged ground.

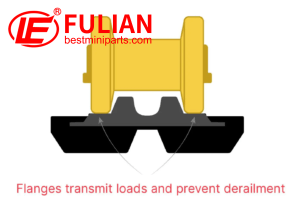

Another crucial function of the track roller is to guide the tracks as they move around the undercarriage. Without the rollers keeping the tracks aligned, you’d quickly run into trouble. Imagine trying to steer a bicycle without wheels—it’s not going to work out well! The track rollers keep the tracks moving smoothly along the correct path, making sure they don’t slip or derail. This guidance is what gives excavators and bulldozers their precise control and maneuverability, no matter how tough the job site gets.

Let’s not forget that track rollers reduce friction between the moving parts of the undercarriage. If you’re familiar with heavy machinery, you know that friction is one of the biggest enemies of efficiency. The more friction there is, the harder the machine has to work, leading to faster wear and tear. Track rollers are designed to minimize this friction, allowing the tracks to roll smoothly over the ground while keeping the undercarriage in good shape. This reduces wear on the tracks, extends their lifespan, and keeps your machine running more efficiently.

At Fulian, we understand that track rollers might not get the attention they deserve, but they’re absolutely essential for keeping your machine in peak condition. That’s why we offer high-quality track rollers that are designed to withstand heavy use and tough environments. Our rollers are built with durability in mind, using high-grade steel and precision engineering to ensure they perform under pressure. Whether you’re dealing with mud, rocks, or uneven surfaces, Fulian’s track rollers are up to the task.

A worn-out or damaged track roller can lead to all sorts of issues, from increased wear on the tracks themselves to costly repairs. If you notice uneven track wear, unusual vibrations, or your machine feels less stable, it might be time to inspect the track rollers. Replacing them when necessary is crucial to preventing bigger problems down the line. And when that time comes, you know who to call—Fulian is ready to provide top-notch replacements to keep your machine rolling smoothly.

In conclusion, track rollers play a vital role in ensuring your excavator’s performance, stability, and efficiency. They may not be the flashiest part of your machine, but without them, your excavator would be a shaky mess. So, give your track rollers the attention they deserve! And when it’s time to replace them, Fulian has you covered with reliable, durable parts. Feel free to reach out if you need more details or have any questions!

Fulian Operation Team

2024.11.15