Alright, let’s dive into the world of excavators and their sprockets, kind of like the vital cogs in a large, earth-moving clock. Picture the sprockets as the big, toothed wheels that engage with the tracks to keep the excavator moving. Just like the tires on your car, these sprockets don’t last forever and need to be replaced periodically to ensure your machine continues to run smoothly and efficiently.

Now, if you’re wondering when exactly you should replace these sprockets, there isn’t one straightforward answer. It’s a bit like asking how often to replace your sneakers. It really depends on how hard you’ve been running them and on what kind of surface.

Generally speaking, the industry suggests a good rule of thumb is to inspect your excavator’s undercarriage components, including the sprockets, every 1,000 operating hours. However, this isn’t set in stone. If your excavator spends its days in harsh conditions, such as navigating rocky terrains or construction debris, you’ll want to check things more frequently. These challenging environments can accelerate wear, meaning your sprockets might need replacing sooner than the average.

When you do these inspections, you’re looking for signs of wear on the sprocket teeth. If they start to look more like shark fins than robust teeth, it’s probably time for them to retire. Delaying their replacement can lead to increased wear and tear on other undercarriage parts, making your excavator work harder and potentially leading to costly repairs down the line.

So, in terms of a replacement schedule, it boils down to keeping a keen eye on wear and tear through regular inspections. If you take good care of your excavator, monitoring its workload and the conditions it operates in, you’ll get a good sense of when those sprockets need changing. It’s about being proactive and understanding that maintaining the small parts can prevent bigger problems.

In summary, while there’s no one-size-fits-all schedule for replacing excavator sprockets, taking the time to regularly inspect and maintain your machine will help you understand when it’s time for a change. This proactive approach ensures your excavator stays in top condition, ready to tackle anything from digging trenches to moving earth, all while keeping your operations running smoothly.

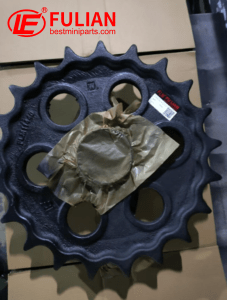

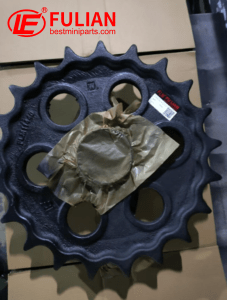

If your excavator’s sprockets are showing signs of wear, don’t wait until it affects your entire undercarriage system. At Bestminiparts, we offer a wide range of high-quality excavator sprockets for leading brands and models, built for durability and performance.

Click here to browse our full selection of excavator sprockets. Can’t find the exact part you need? Contact us today—our team is here to help you get the right part fast and hassle-free.

Fulian Operation Team

2024.7.3