Understanding when to replace the sprocket on your excavator is essential to maintaining optimal performance and extending the lifespan of the machine. Here’s a guide to help you identify the signs that it’s time to replace your excavator’s sprocket.

Visual Inspection:

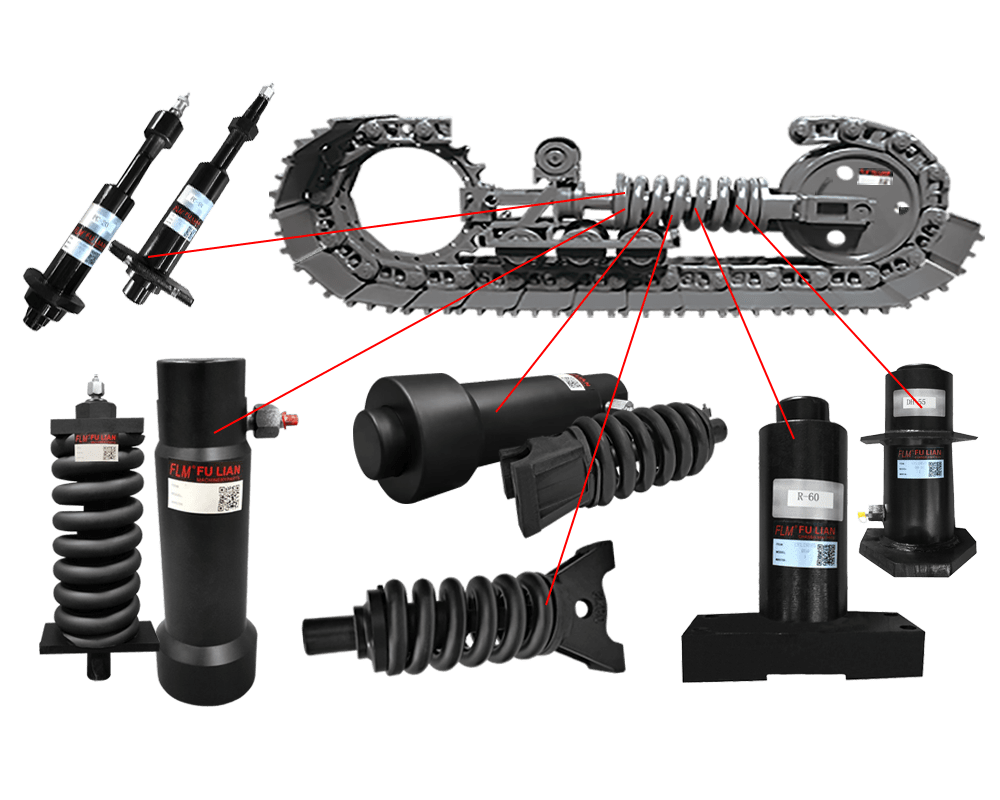

A thorough visual examination of the sprocket is the first step. Look for these critical signs:

-

Teeth Wear: Sprocket teeth should have a uniform, rounded appearance. Sharp or pointed teeth are an indication of excessive wear.

-

Tooth Shape: The teeth on a new sprocket have a specific shape and width. If they look ‘shark-fin’ shaped, thin, or extremely worn, it suggests replacement is needed.

-

Breakage and Damage: Broken or chipped teeth can impair the sprocket’s function and can also damage the tracks.

Operation and Performance:

Monitoring the performance of your excavator can provide clues about the state of the sprocket:

-

Excessive Noise: A worn sprocket may cause a rattling or clanking sound as it interacts with the track.

-

Track Slippage: If the track seems to slip or jump, especially under strain, this could indicate that the sprocket’s teeth are worn down and not engaging properly.

-

Unusual Machine Movement: Difficulty in maneuvering or unusual movements may show that the excavator’s traction is compromised due to a worn sprocket.

Frequency of Track and Sprocket Replacement:

Have a standard maintenance schedule. While tracks may be replaced more frequently, a worn sprocket can rapidly increase track wear, indicating both need replacement at the same time.

Post-Assessment Steps:

Upon confirming that a sprocket replacement is necessary, follow these steps:

-

Source the Correct Part: Obtain a sprocket that is compatible with your excavator model.

-

Engage in Safe Practices: Always ensure the excavator is placed on stable ground and follow the manufacturer’s safety guidelines.

-

Disassembly: Release the track tension before removing the old sprocket to avoid undue strain on the machine.

-

Installation: Fit the new sprocket and secure it with the proper bolts and fittings as per the specifications.

-

Track Tension: After the new sprocket is installed, make sure to correctly adjust the track tension.

-

Expert Consultation: If you are unsure about the process or its intricacies, consult or hire a skilled technician to execute the replacement.

Regular check-ups will alert you to the need for replacements before they become critical. Proper maintenance not only guarantees the longevity of your excavator but also ensures it operates at peak efficiency with minimal downtime.

Fulian Operation Team

2024.5.31