When it comes to selecting the most durable material for mini excavator tracks, the debate often resembles choosing the perfect pair of shoes for a marathon—you need something that not only fits well but can also endure the relentless pounding of daily use. In the world of heavy equipment, durability and reliability are paramount, and the material you choose for your tracks plays a pivotal role in ensuring long service life and reducing downtime.

Let’s break it down in a way that’s both informative and a bit lighthearted. Traditional steel tracks have long been the go-to choice for many excavator operators. Steel is like that trusty pair of boots that have seen you through countless adventures—robust, reliable, and ready for anything. Its high strength and excellent wear resistance mean that it can handle heavy loads and abrasive conditions with ease. However, steel isn’t without its drawbacks. It can be heavy, and sometimes the rigidity of steel doesn’t allow for as smooth a ride as you might prefer, especially on uneven terrain.

On the other side of the ring, you have rubber tracks, which are akin to cushioned sneakers designed for comfort. Rubber tracks provide superior shock absorption and are considerably lighter than steel, making them ideal for operators who need a machine that is both agile and gentle on delicate surfaces. They also offer a quieter operation—a welcome bonus if you prefer your machine to run more like a whisper than a roar. But here’s the catch: while rubber is excellent for reducing vibrations and minimizing surface damage, its wear life under extreme conditions may not match that of high-grade steel.

What about advanced composite materials? Some manufacturers have begun to experiment with reinforced composites that blend the best qualities of steel and rubber. These materials are engineered to deliver enhanced durability while reducing weight, though they often come at a higher initial cost. For many, the investment is justified by the long-term savings in reduced maintenance and extended service life.

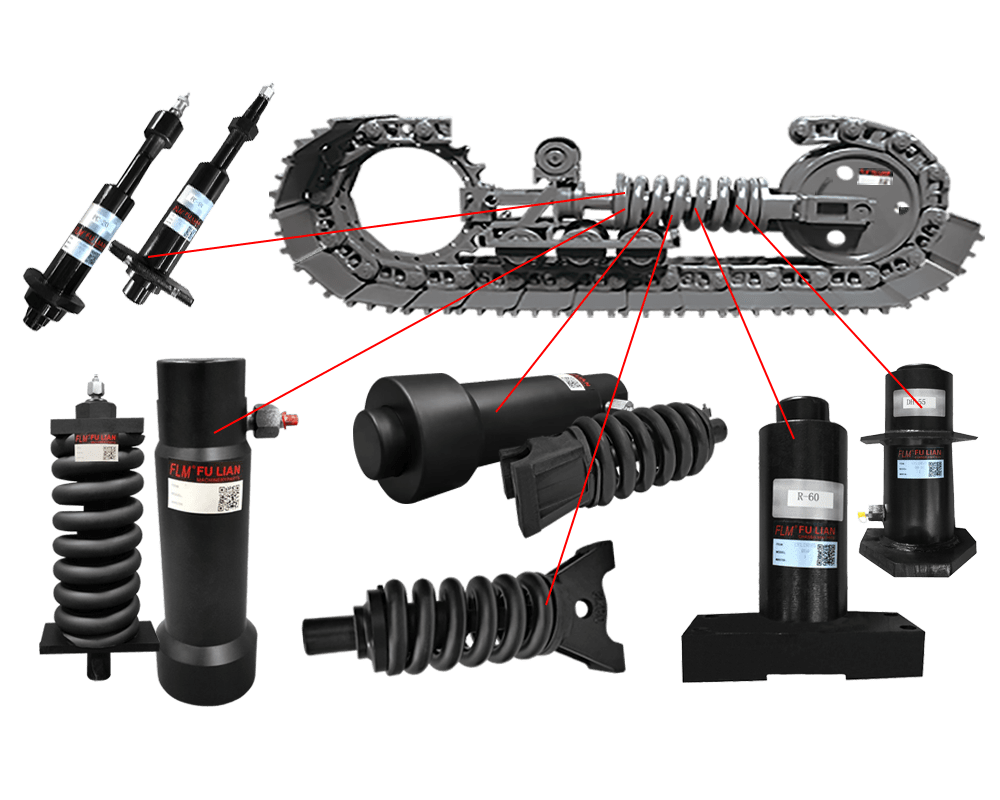

At Fulian Machinery, we pride ourselves on offering a range of high-quality undercarriage components, including tracks made from both premium steel and advanced composite materials. Our expertise lies in understanding the specific needs of each application. For example, if you’re operating in harsh, abrasive environments where heavy loads and rough terrain are the norm, our high-strength steel tracks are engineered to provide exceptional longevity and reliability. Conversely, if your work demands a quieter, smoother ride with less impact on sensitive surfaces, our rubber-based tracks might be the ideal choice.

Ultimately, the “better” material for mini excavator tracks depends on your specific operating conditions and priorities. Do you need the relentless durability of steel, or the cushioning comfort and versatility of rubber? Perhaps you’re ready to explore cutting-edge composites that offer a balanced blend of both worlds.

If you’re not sure which option is best for your fleet, don’t worry—our team at Fulian Machinery is here to help. We bring years of industry expertise and a commitment to quality that ensures you get the right parts for the job. Contact us today to discuss your requirements and let us guide you to the most durable, cost-effective solution for your mini excavator tracks.

Fulian Operation Team

2025.2.21