If your excavator track keeps coming off, it’s more than just a frustrating nuisance – it can be a real jobsite headache! There are several reasons why this can happen, and understanding them will not only save you time but also keep your project on track (pun intended). Let’s break it down and figure out what might be causing your tracks to pop off and how to fix it.

1. Loose Track Tension

One of the most common culprits behind frequent track issues is loose track tension. Think of your track like a pair of shoelaces – if it’s not tight enough, it’s bound to slip off. Over time, the natural wear and tear on your excavator can cause the track tension to loosen, especially when you’re working on uneven or rocky terrain. A quick solution here is to check the tension regularly. If the track seems loose, you can adjust it yourself or bring in an expert to tighten it back up. A properly tensioned track will stay snug and keep you moving smoothly.

2. Worn-Out Components

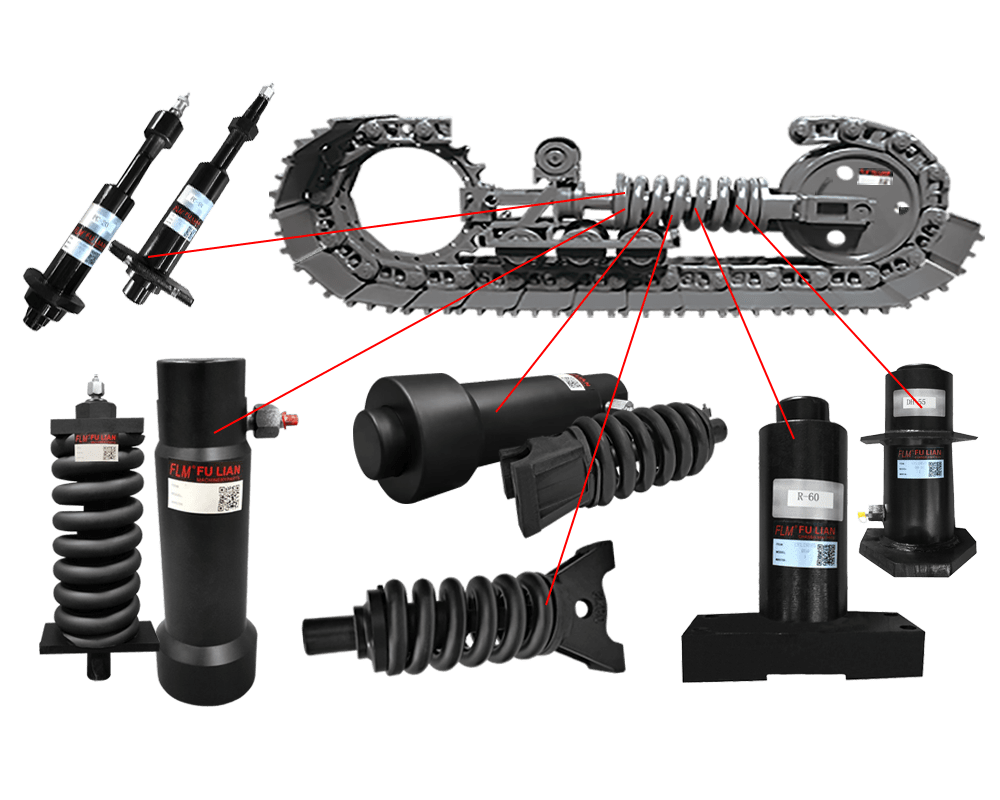

Tracks rely on several undercarriage components to stay in place, including rollers, idlers, and sprockets. If any of these parts are worn out, the track might not stay aligned properly. A worn-out sprocket can cause the track to skip off, especially when reversing. Similarly, if your rollers or idlers have seen better days, they might not be guiding the track as they should. Regular maintenance of these parts is crucial – think of them as the unsung heroes keeping your track in line. Fulian offers durable undercarriage components designed to withstand wear and tear, helping to keep your tracks where they belong.

3. Misaligned Track Frame

Sometimes, the issue is structural. If your track frame is bent or misaligned, the track may have a hard time staying on. This can happen after an impact or from long-term wear. A misaligned frame can cause the track to veer off to one side. If you suspect this is the issue, it’s best to have a professional take a look and make the necessary adjustments. Regular inspections will catch this problem before it gets worse.

4. Debris Buildup

Another sneaky cause of track slippage is debris. Rocks, mud, or other material can build up between the track and undercarriage, preventing the track from seating properly. This is especially common if you’re working in muddy or rocky conditions. After a day’s work, it’s a good idea to clear out any debris that’s accumulated around the track. A clean undercarriage will not only prevent the track from coming off but also extend the life of the components.

5. Incorrect Operating Habits

Finally, how you operate the machine can also affect the track’s performance. Sharp turns, especially when pivoting on one spot, can put a lot of stress on the track and cause it to come off. Try to make wider turns whenever possible and avoid unnecessary spinning. Proper operating techniques will reduce the strain on your tracks and keep them in place longer.

Get the Right Parts from Fulian

If your track keeps coming off, it’s time to take a closer look at your undercarriage. At Fulian, we specialize in high-quality undercarriage components that ensure your machine operates smoothly. Whether you need new sprockets, rollers, or tensioners, our parts are designed to handle the toughest conditions. Don’t let loose tracks slow you down—reach out to us for expert advice and top-notch products that will keep your machine running smoothly.

Explore our full range of undercarriage parts on our website and find the perfect fit for your equipment. Whether you’re maintaining a mini excavator or a heavy-duty dozer, we’ve got the reliable components you need.

Visit Fulian’s official store to browse undercarriage parts and request a quote today.

Feel free to contact us if you need more details or have any questions!

Fulian Operation Team

2024.11.22